Application HQ

The conveyor belts HQ in combination with our metal detectors of the BD-HD series result in a high-sensitivity and highly reliable device for the detection and the separation of metal. All devices are manufactured individually according to your requirements. The construction as well as the manufacturing of the HQ series are completely realised in our headquarters. Due to this fact and to our expertise we provide for the optimum solution for each of your assignments. Our plants are used in all branches of industry. Particularly they serve for the inspection of singular goods or bulk material. The robust design in stainless steel stands for longevity and comes up to strict hygienic standards.

Function

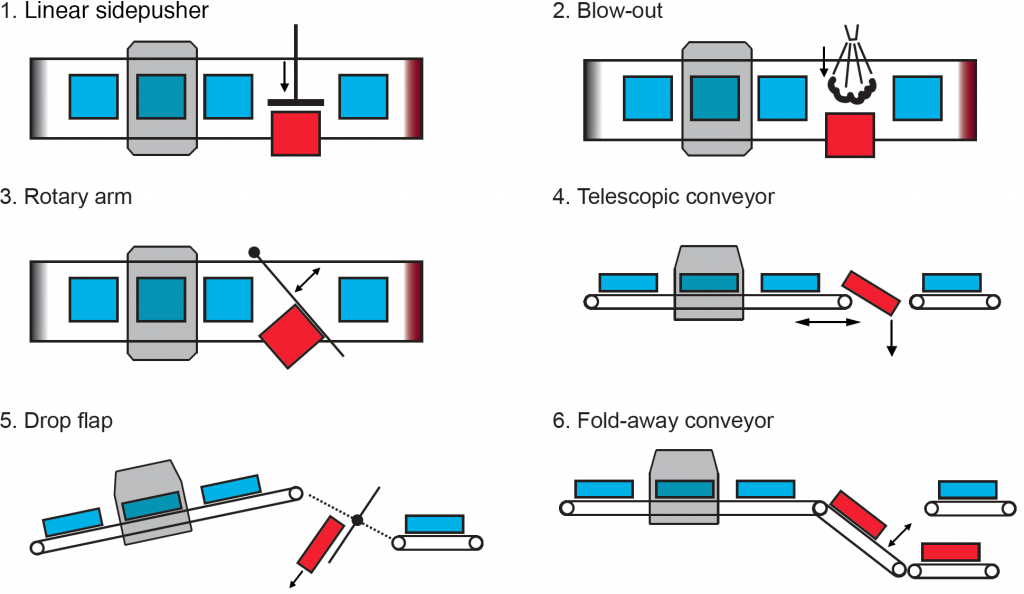

The conveyor belt leads the test material trough the metal detector. The detector scans the products and analyses the data in real-time. Powerful processors allow a high-precision fade-out of the product effect. Furthermore interfering influences as for example vibrations can effectively be eliminated. Even at high velocities the device works reliably and precisely. If metal is detected in the test material, there are different possibilities for the separation of the contamination. The easiest way is to get the conveyor belt stopped automatically and to remove the contamination manually. After that the conveyor belt restarts at the push of a button. For highly automated manufacturing plants we recommend a separating system that works automatically. Thereby the metallic contamination is detected precisely by a light barrier. Thus the position of the contamination in the product stream is clear and the metallic residua can be separated. If there are several products in the sensor range at the moment of the detection of metal, the high-performance technology allows the automatic exclusion of all questionable products. There are different principles for separating the contamination:

Specific characteristics

• speed-controlled, high-capacity engine

• high-performance fade-out of product effect

• various separating attachments available

• belt available in different materials and designs

• special designs (curved conveyors, elevating conveyors etc.)

• height adjustable and optionally mobile

• clean and solid treatment

• customized designs

Equipment

All conveying plants are serially equipped with an adjustable engine. The conveyor belt, an open link chain conveyor, is even and without curves. It possessed height adjustable stands (±50 mm) without ear. The power switch, the emergency stop button and the start/stop button are serially integrated. The entire frame construction as well as the switch cabinet are made of stainless steel and are fully capsuled (IP 65). Information concerning the sensitivity are given in the data sheets of the BD-HD series. Equipment for the control electronics you will find in the data sheets of the electronic M-Pulse2.

Accessories & options

Next to separating filters there are many other additional components for our conveyor plants. Below is a list of all the standard options.

- safe for contaminated products

- design: elevating conveyor

- design: curved conveyor

- belt material – link chain closed

- belt material – polyurethan

- design: belt conveyor

- signal light – alarm for metal detection

- signal light – performance test

- signal transmitter – alarm for metal detection

- side guidance fixed

- side guidance adjustable

- fill level control for safe

- compressed air monitoring

- ejection monitoring

- protection class IP67

- guide pulley with fixation

- stands with ears

- touch panel

If other requirements need to be met, a customized solution is possible as well.